In 1570 the historian William Lambarde wrote in his ‘Perambulations of Kent’:

‘…There are to be seen … near this town … sundry artificial caves or holes in the earth, whereof some have ten, some fifteen and some twenty fathoms in depth: at the mouth (and thence downward) narrow, like the tunnell of a chimney or passage of a well: but in the bottom large, and of great receipt: insomuch as some of them have sundry rooms (or partitions) one within another, strongly vaulted, and supported with pillars of chalk, and, in the opinion of the inhabitants, these were in former times digged, as well for the use of the chalk towards building, as for to marle their arable lands therewith…’

Lambarde was describing the excavations which have become known as deneholes. The term denehole (or dene-hole, dene hole or danehole) is semi-modern in usage, the earlier writers on the subject describing them as ‘pits’. The particular holes mentioned above were in Stankey Wood near Bexley and Crayford.

A denehole is an underground structure consisting of a number of small chalk caves entered by a vertical shaft. The chalk uplands of Kent once contained many hundreds, if not thousands, of deneholes of various types and the origins and purpose of these man-made excavations were the subject of intense interest and debate in the latter 19th century. Some of the open shafts were visited by Victorian historians who descended into the caves and produced drawings and surveys of varying quality. One of the most useful to the modern researcher was the eminent antiquarian F.C.J. Spurrell’s paper ‘Deneholes and Artificial Caves with Vertical Entrances’, published in the Archaeological Journal for 1881 and 1882.

At this time, many theories were put forward to explain why these structures were excavated, varying from Druids’ temples, flint mines and ancient hiding places to elaborate animal traps. By the end of the 19th century, however, opinion had polarised between ancient grain storage pits and chalk mines. It seems that the chalk mine idea was not too popular despite Lambarde’s observations 200 years before. After all, a simple chalk mine is not as romantic as a Druid’s lair or a neolithic grain store! In the early 1950s, a very active and competent amateur archaeologist, J.E.L. Caiger, brought the eye of a professional engineer and surveyor to bear on the denehole controversy. His investigations over many years included detailed surveys, surface and underground excavations and documentary research which added greatly to our store of knowledge.

From Caiger’s pioneering work and subsequent investigation and research by the Kent Archaeological Society and Kent Underground Research Group, it can now be stated that deneholes are no more than small chalk mines. The vast majority were sunk to obtain an unpolluted supply of chalk to spread on the surrounding fields as a fertiliser. The method had much to recommend it as a small shaft at the edge of a field would not interfere with farming operations and could easily be blocked when mining ceased. Opencast extraction would, on the other hand, have meant the removal of a thick overburden and the loss of precious arable land. This method of winning chalk was in use in Kent before the Roman conquest and continued in varying forms, with a brief break in the 15-16th centuries, until the turn of the present century. In fact, whilst the archaeologists were arguing as to the age and use of these mysterious holes in the 1880s, similar excavations were still being dug, often in the same areas as their older counterparts!

To modern eyes, it is puzzling why a shaft would be sunk when chalk might occur almost at surface nearby. The simple answer to this is that the shallow chalk was probably not on the farmer’s property since land tended to be owned in much smaller parcels then. In addition, the old roads were in very bad condition and it was too difficult to carry heavy loads any distance in a cart. Another reason for deep extraction was that farmers preferred chalk from a depth, saying that it was ‘fatter’. This has some truth in that chalk near the surface usually has various elements such as magnesium leached out.

Deneholes/Chalkwells

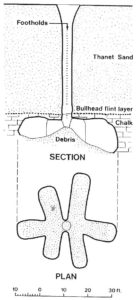

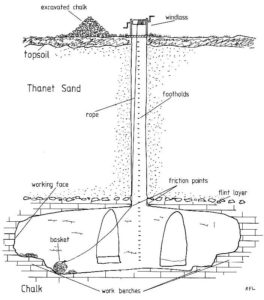

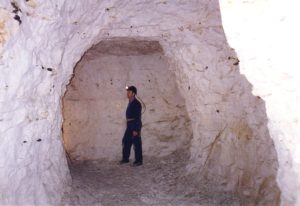

Although there are many variations of the basic denehole ground plan, there are two distinct types. Within the two main types there exist variations in shape depending on the mining techniques employed and there are also regional differences as separate mining teams developed their own particular style. The first (and regarded as earlier) type consists of a narrow shaft, about 3ft in diameter, sunk through the overlying strata (usually Thanet Sand) until the chalk was reached. Footholds were cut on opposite sides of the shaft so that miners could climb in and out without a ladder. After reaching the chalk, a number of chambers were excavated and these were often in two sets of three to give a double cloverleaf or trefoil pattern. This type was being dug up until the late 14th century and is usually referred to as the true denehole.

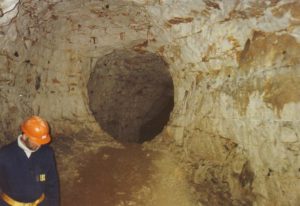

The second type is generally known as a chalkwell (or draw well) and was sunk in areas where the chalk was overlain by a heavy soil such as clay. The shaft of these types is wider, from 4-6ft in diameter, and the chambers consist of between 2-4 roughly cut caves radiating from the base of the shaft. This type was being dug from the 17th century right up to the beginning of this century.

Uses of Chalk

The vast majority of deneholes were dug to obtain a supply of chalk to spread on the local fields as a top dressing, a process known as chalking or marling. Chalk is lost or ‘leached’ from the soil at a rate depending on rainfall and soil texture and an application of chalk will replace the lost calcium. On clay based soils, marling will help to break up the heavy soil and will assist drainage. On acidic soils, such as those lying on Thanet Sand, chalk will neutralise or ‘sweeten’ it. Chalk was traditionally mined and spread on the fields in late autumn so that the nodules of chalk would be broken down and powdered by the winter frosts, ready to be ploughed into the soil in the following spring. The use of chalk as a fertiliser has been known for many centuries and the Roman historian, Pliny the Elder, wrote in 70 A.D. about the ancient British mining it for this purpose.

‘…the chalk is sought from a deep place, wells being frequently sunk to 10Oft, narrowed at the mouth, the vein spreading out within as in mines. This is the kind most used in Britain. It lasts for 80 years and there is no instance of anyone who has put it on twice in his lifetime…’

Old Norman leases often contained covenants to ensure that chalk was regularly applied to the land and a statute of Henry III in 1225 gave every man the right to sink a marl pit on his own land. Although the primary use of chalk from deneholes and chalkwells was for agricultural use, the excavated material could be, and was, used for building and for road making and repairs. It is also possible that some of the smaller brickfields obtained a supply of chalk from chalkwells rather than excavating a quarry or larger chalk mine. Some were associated with limekilns since lime mortar was used to bond together bricks before cement was invented.

Mining Methods – Deneholes

The shaft was sunk as close as possible to the field boundary so that any future subsidence would not interfere with ploughing operations. Many deneholes can be found in distinct association with earthwork boundaries. In some areas, the miners would have a problem if the Thanet Sand, which is relatively stable, was overlain with a loose material such as gravel. If this layer of loose and friable material was less than 2ft deep, the area of the shaft would be cleared of gravel before shaft sinking commenced. This would prevent the loose material running in on top of them as the shaft was sunk. This method of making the shaft top safe was used in the Bexley area, particularly at the site of Stankey Wood. If the layer of gravel was too thick to be easily cleared away, the miners would line the top of the shaft with a wicker basket type of construction to prevent run-ins. Another method was to line the shaft top with roughly squared flints or chalk blocks (steining) as was found in a denehole near Swingfield.

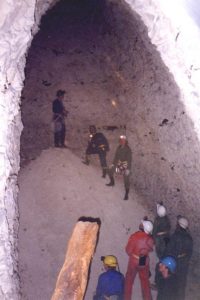

Once the spot for the shaft had been chosen and cleared as necessary, it would be sunk vertically through the Thanet Sand, using the hauling rope and basket as a plumb line, until the chalk was reached. After leaving about 3ft for roof thickness, two opposing headings were commenced as the start of the usual double trefoil plan. Some early writers marvelled at the symmetry of the two sets of chambers and the care with which they were constructed, comparing them with the building of cathedrals, etc. The excavators had in fact developed the most efficient shape for extracting the maximum amount of chalk with the minimum of effort. They were constructed with care to ensure stability and reduce the risk of roof fails. The excellent finish and obvious knowledge of mining techniques indicates that most deneholes were dug by groups of professionals hiring out their services to the local farmers.

A mining team would have consisted of three men. One would work below ground cutting out the chalk using a short-headed iron pick, working forward in a series of steps or ‘benches’. These abandoned benches have, in the past, led to tales of Druids’ altars, etc! The chalk was hauled to the surface in a basket by the miner’s two companions, using a small windlass mounted over the shaft. The length of the underground chamber was determined by the friction generated by the hauling rope on the chalk at the base of the shaft. When the majority of double trefoil deneholes were being dug, the wheelbarrow had yet to be invented so transporting the chalk for any distance underground would have been a problem. The miner thus filled the basket at the working face and, when the above friction became too great for the surface workers to haul it up, the end of the chamber was trimmed and that part of the mine considered finished. Most deneholes have deep grooves visible at the base of the shaft where the hauling ropes have cut into the soft chalk.

When excavations had ceased in the denehole, a bush or tree stumps were thrown down the shaft. These would invariably jam part way down and the shaft was then backfilled to surface. Many denehole sites are now in woods or long narrow copses (known locally as ‘Shaves’ or ‘Shaws’) where farmers have planted trees in the past to isolate the area. Very few deneholes are still accessible but one at Darenth Wood can be entered by sliding down a slope where one of the chambers has collapsed.

Mining Methods – Chalkwells

Once again the shaft was sunk as close as possible to the field boundary, although some mining teams preferred to place the shaft in the centre of the field to be chalked. The chambers or ‘wells’ (usually three) were cut radially from the shaft. As the shaft was wider than the earlier types of denehole, the miner could not climb down -and so was lowered on a rope by his colleagues. In some chalkwells, the shaft diameter increased as it went down so that rope friction was less of a problem and artificial light was not always necessary.1n some examples, the length of the chambers are such that the chalk must have, been transported to the base of the shaft by wheelbarrow. When enough chalk had been removed the chalkwell was sealed, usually by installing a brick dome about 6ft down the shaft and backfilling to surface. When the brickwork fails, the shaft will open up.

From early writers we know that in the 17th century a mining team of three men would charge £10 to dig a chalkwell large enough to chalk a field of 6 acres. It would yield 360 tons of chalk i.e. a dressing of 60 tons per acre. If more than 6 acres needed treatment, the miners insisted on digging another shaft – for another £10 of course! A number of chalkwells were dug by local farm labour when work was slack and these tend to be rougher and less stable than those dug by professionals. For those wishing to inspect a typical chalkwell in safety, a visit to Kent County Nurseries at Challock will be of interest. The ‘Exotic Grotto’ there is in actual fact a three-chambered chalkwell with a spiral staircase down the shaft. If you ignore the claims of it being a Neolithic flint mine (as well as the gnomes and plants inside!) you will be able to see how it was excavated.

Groups of Deneholes

Although most deneholes are found singly and in distinct association with ancient field boundaries, some are found in groups of up to 70+ separate shafts. Great care was taken by the miners in these groups that individual deneholes did not communicate underground. Sometimes less than 3ft of chalk would separate two deneholes and this was to ensure the overall stability of the area and reduce the risk of subsidence. Two of the largest groups are near Bexley, with 35+ at Cavey Springs and 50+ at Stankey Wood. Since it would be both impractical and uneconomic to transport excavated chalk for any distance, a denehole was dug as close as possible to the field it served. The amount of chalk brought out of the denehole groups, however, far exceeds that required for top dressing, even if the group had been worked over long periods. it is therefore probable that the chalk was used for other purposes as well. The deneholes of Cavey Springs, for example, almost certainly supplied chalk blocks for building purposes. Archaeological excavations and observations in Bexley village have shown that several medieval buildings had footings of chalk blocks. No doubt the chalk was also used on the local fields and some could have been burnt in simple limekilns in the vicinity of the mines.

The simplest, and almost certainly the earliest, type of denehole consisted of a very shallow bottle-shaped chamber, no more than 30ft deep. F.Q. Spurrell investigated a small number of these at Crayford in the late 19th century and he considered that they had been dug with deer antler picks. He had the mound of debris below the shaft carefully removed and found ‘worked flints’ and some Roman pottery. it is now realised, however, that you cannot conclusively date a denehole from what has fallen down the shaft. If the shaft had been dug through an earlier site, for instance, artefacts could fall out of the shaft sides at any time and give false evidence. in addition, pottery, etc. lying in surface soil can be washed into an open shaft after it has been abandoned. The unreliability of this method of dating was proved by R. Le Gear in 1964 whilst directing an excavation in a denehole near Dartford. A small fragment of Roman pottery was found but further down (indicating an earlier date) was a Victorian chamber pot! The pottery had in fact been washed into the shaft from a site further uphill.

The simple single-chambered denehole developed into a shaft with three short chambers radiating from the bottom. From this evolved the most prolific type found in North West Kent i.e. the double trefoil with two sets of three chambers on either side of the shaft. This was an extremely good design combining efficient one man underground operations with structural stability. The mines of Stankey Wood in Bexley took the double trefoil one stage further by cutting away the sections of chalk separating the chambers, leaving up to six pillars to support the roof. This decreased the safety margin but increased output by up to 50%. Denehole excavation peaked around the 13th-14th centuries when large areas of virgin woodland were being grubbed out and brought into agricultural use to satisfy the demands of an increasing population. Much of the woodland chosen was on a subsoil known as Thanet Sand which is slightly acidic or ‘sour’ and an application of chalk from deneholes was required to ‘sweeten’ it and thus improve productivity.

During the 15th-16th centuries, the skill of sinking deneholes was apparently lost. One reason for this is believed to be the result of a sharp decrease in population (up to a third in some areas) following the outbreak of the Black Death. This hit England in 1349, with reoccurrences in 1362 and 1369, and from then on bad outbreaks occurred almost every decade. Another reason could be the introduction of sheep to the area at this time, with many fields turned over to grazing rather than crops. This decrease in agricultural demand meant that the skills of the denehole miner were no longer required, since there was now a surplus of cleared land.

By the 17th century, however, the population was once more on the increase and there was a demand for more woodland to be cleared for cultivation. It was now the turn of woodland on heavy clay soil to be cut down and chalk was required to break up the clay and assist drainage. Once again, shafts were sunk and chalk spread onto the fields. Now, however, the carefully efficient mining techniques of two centuries before had been lost and a new type of denehole was born, the chalkwell. The double trefoil pattern was no longer used and the excavations were much rougher in finish.

This type continued to be dug right up to the turn of the present century. Possibly the last ever denehole to be dug in Kent was excavated near Doddington by ‘Tokey’ Higgins between 1904-08. Fortunately, he was interviewed by a KURG member, Jim Bradshaw, shortly before his death in 1976 at the age of 92.

‘…1 had a small quarry and lime kell (kiln) just above the “Chequers” on Chequers Hill and, after an argument with the owner of the land, had to leave them. To stay in business, 1 moved up the hill on the same side and, on a small bit of ground, 1 built a brick kell and sank a draw well. This was in 1904 and at first 1 pulled up the chalk in baskets by hand with an old well-top windlass but later used an old horse that walked downhill and brought it up by block and tackle. 1 worked as a casual day labourer on the farms and lime burning was a “fall back” job. When the well was 20ft deep, 1 began to widen it as the old timers did until 1908 when I gave it up.’

This shaft has presumably now been filled since a bungalow has been built on the site. It must be stressed, in closing, that deneholes are dangerous places to explore since many are now in an unstable condition. In addition, hollows found in woods should be avoided since they could be denehole sites

More information can be found here denehole.wikipedia.org